We are thrilled to announce the launch of our innovative support structure, the J-Tube Ramp.

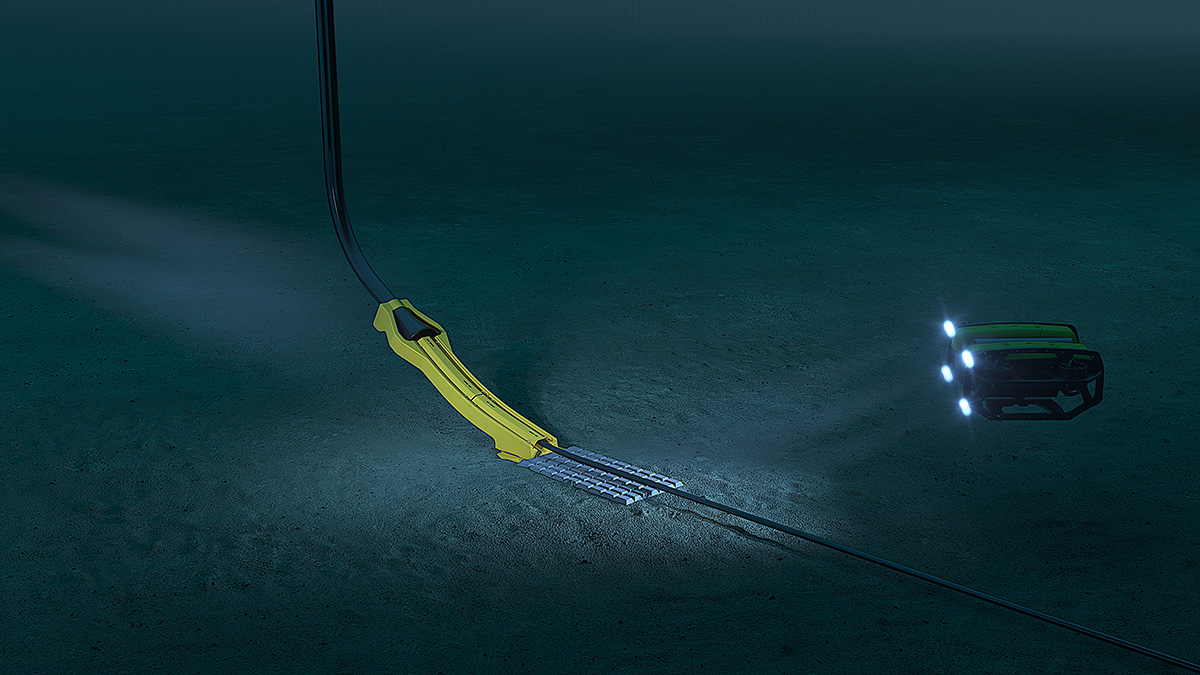

CSUB is releasing a J-Tube Ramp. This is a specialized support structure designed to protect and support subsea cables where they connect to offshore structures through J-Tubes, without the need for additional locking equipment. This latest addition to CSUB’s comprehensive non-metallic product portfolio represents a significant advancement in subsea infrastructure protection technology.

– This innovation demonstrates our commitment to developing sustainable, efficient solutions for the subsea sector. Our J-Tube Ramp exemplifies how smart engineering can simplify complex offshore operations while maintaining the highest safety and reliability standards, says Bjørn Fossestøl, VP of Engineering at CSUB.

Easy Installation Process

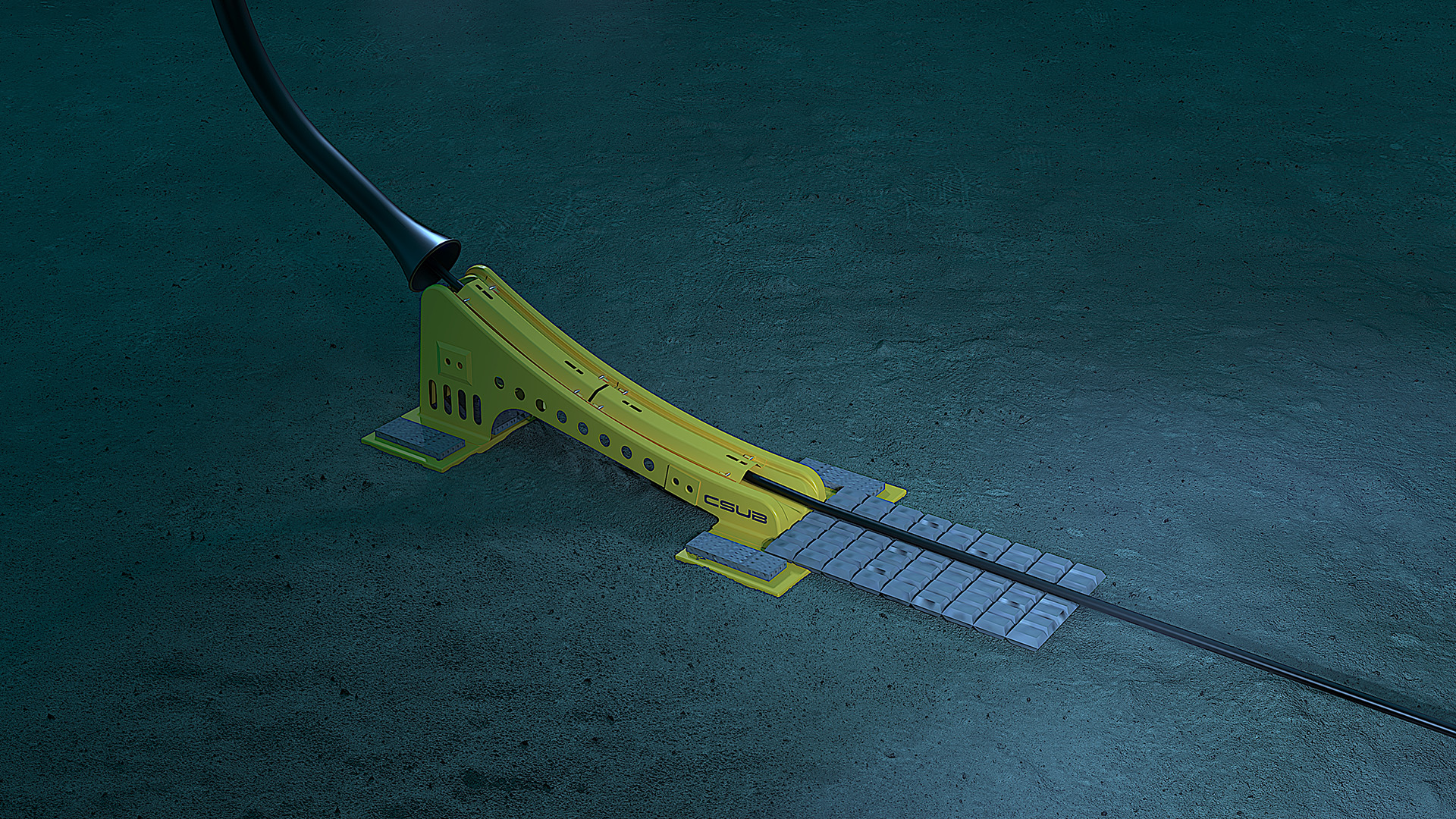

This innovative support structure is designed with a base portion that rests on the seabed, accompanied by a support channel with a curved design leading up to a specialized receiving structure. What makes the ramp unique is its smart attachment system. The top cover is equipped with a unique integrated self-locking interface towards the ramp – simplifying the installation and consequently reducing installation costs.

– By simply sliding the ramp you can attach the cable in to place. It’s a self-securing design that prevents uplift and significantly reduces installation time compared to traditional methods, explains Fossestøl and adds that specialized contact elements are installed to prevent friction damages to the tube.

The method of installation allows for installation in confined spaces where ROVs traditionally haven’t been able to reach.

– Without any problems ramps can now be installed in very tight spaces where the J-tubes are located close together. Our ramps revolutionary design substantially reduces installation time and costs, says the engineer.

Made for Offshore Structures Worldwide

The ramp is compatible with a wide range of tube diameters and can be designed to accommodate different seabed conditions. Making it a versatile and viable alternative for various offshore structures worldwide, including offshore wind turbines, offshore substations and offshore rigs.

– Before manufacturing, CSUBs J-Tube Ramps are individually tailored by our engineers to meet each projects needs and requirements. We can easily make ramps up to 4 meters and longer to achieve the proper support that is needed, says Fossestøl.

Despite its big size the ramp is lightweight, which is one of the many advantages of the material GRP.

– This offers great cost savings when it comes to transportation and installation. It minimizes vessels and cranes requirements resulting in lowered costs and emissions.

The benefits of GRP

CSUB has risen to be the world’s largest EPC-supplier of non-metallic subsea constructions. Utilizing all the benefits from GRP to make long-lasting support and protection structures, we are now an industry leader with our knowledge and expertise.

– GRP is an environmentally sustainable material that significantly reduces the carbon footprint compared to traditional solutions using materials such as steel. Its non-metallic, lightweight design reduces the need for large installation vessels, while its exceptional durability eliminates future maintenance and replacement—delivering a long-term, sustainable alternative to conventional systems, explains Fossestøl.

– The J-Tube Ramp aligns perfectly with CSUBs commitment to create efficient, durable subsea structures. We are thrilled that we now can make our invention public and have great faith that this will be a gamechanger for the subsea industry. This solution offers reduced installation time, enhanced safety and long-term reliability for your subsea cable systems, ends CEO, Anders Holm.

Read more about the J-Tube Ramp here.