How CSUB’s Innovations in Composite Material Tackles Industry’s Biggest Challenges

Non-metallic subsea structures meets the needs of the Middle Eastern market.

The landscape of Oil & Gas operations in the Middle East is evolving rapidly, facing a unique set of challenges that demand innovative solutions. As the region maintains its position as a global energy leader, industry executives are increasingly turning to breakthrough technologies to address their most pressing operational concerns.

For CSUB our presence in the Middle East began in earnest with a delivery to the North Field Production Sustainability Project back in 2022. With presence in both Qatar and the Emirates we are now strengthening and broadening our availability in the Middle East. Bringing innovative and pioneering solutions to face the challenges the region experiences.

– CSUB offers non-metallic subsea constructions. We are the world’s largest EPC-supplier regarding Glass Fiber Reinforced Polymer (GRP), with decades of experience. Our people are experts at engineering and fabricating composite subsea structures, tailored to meet the specific challenges the Oil & Gas industry in the Middle East faces, says CSUBs general manager in the Middle East, Mathias Berg.

Solves Capacity Issues

While demands are increasing, production bottlenecks are one of the challenges for operators in the current market. Traditional solutions, such as concrete, require large manufacturing areas and has a long curing time. The characteristic of GRP makes it possible to get rid of a lot of these constraints.

– Traditional concrete or steel structures require extensive space and time, creating substantial bottlenecks in production schedules. Our material and method of production allows us to produce structures using only a sixth off the area utilized to produce an equal number of structures in steel. You’ll also save time in regards of curing compared to concrete, says Berg.

– This is a gamechanger when it comes to manufacturing. It leads to increased capacity and can expand the overall production volume in the country in question. One of the advantages of our non-metallic solutions is the flexibility when it comes to design. We tailor each individual piece to accommodate the clients’ needs and wishes, creating a comprehensive solution in the end, adds Berg.

CSUB is bringing its expertise to the region through a strategic partnership with Qatar Shipyard Technology Solutions. This agreement ensures short delivery time for clients in the Middle East.

– Our partnership ensures that Middle Eastern operations have immediate access to world-class solutions, supported by local expertise and rapid deployment capabilities. Making development of new oil and gas fields eco-friendlier and more cost effective. We are confident that Qatar Shipyard Technology Solutions are the right partner for us and are mighty impressed by the quality of work, and the HSE handling, we have seen so far, says CEO of CSUB, Anders Holm.

Significant Cost Savings on Overall Expenses

In an industry where every operational decision impacts the bottom line, the financial benefits of GRP solutions are compelling. The stackable design and lightweight nature of these structures are creating ripple effects throughout the supply chain.

– By choosing non-metallic structures, shipping will require less deck space, smaller vessels and fewer campaigns, resulting in time and fuel saved, Berg says and adds – As a bonus this will also lead to lowered C02-emissions, making GRP a greener alternative all over.

Safe Installation and Reduced Risk of Damage

When dealing with existing infrastructure worth millions, you can’t afford installation risks.

– Our lightweight solutions have dramatically reduced the complexity of installation operations. We’re seeing projects completed with smaller cranes, fewer lifts, and significantly reduced risk to existing infrastructure, such as pipelines, says Berg.

After the installation is completed, you will continue to benefit from composite for years to come. Because of the materials characteristics you’ll avoid the typical maintenance cost backlog.

– Our composite solutions have a design life of 50+ years. Because of the material’s non-corrosive properties our products are virtually maintenance free, says Berg.

– When you consider the reduced shipping requirements, simpler installation processes, and virtually zero maintenance over a 50-year lifespan, we’re looking at substantial long-term financial benefits. In today’s market, this kind of operational efficiency is invaluable, Berg adds.

Environmental Leadership

With significantly lower carbon footprints in manufacturing, transportation, and maintenance, GRP solutions are helping operations meet and exceed environmental standards while maintaining operational excellence. Our products are well tested and recognized by major players in the industry. Over the years our portfolio has evolved, now including a variety of support structures and protection systems.

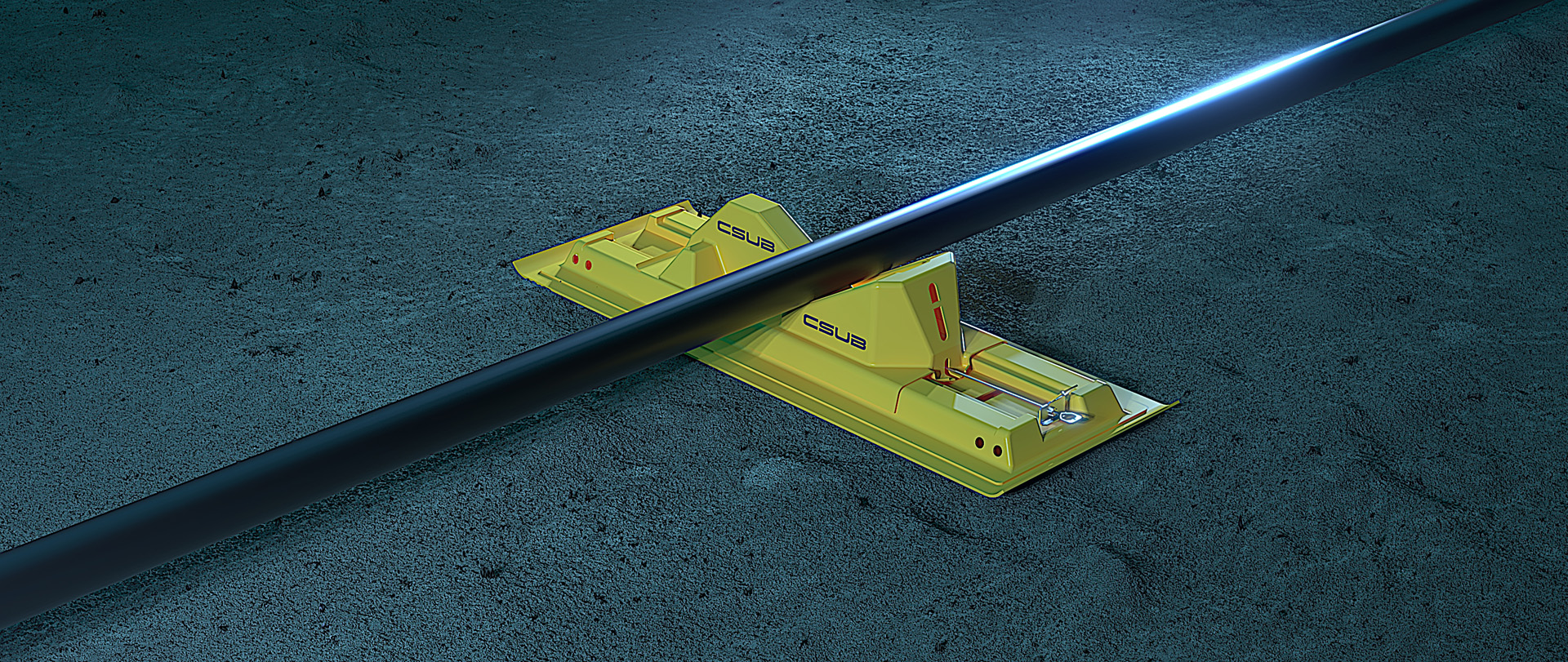

Subsea Sleepers and Buckling Initiators

CSUB’s Sleepers are robust structures specifically designed to support and stabilize subsea pipelines. They play a crucial role in controlling lateral buckling caused by thermal expansion and contraction and are vital for maintaining the integrity of pipelines over their operational lifespan.

CSUB’s buckling initiators are engineered to ensure that subsea pipelines buckle in controlled, predetermined locations or patterns, significantly reducing the risk of unexpected or harmful buckling. While sharing key quality features with CSUB’s sleepers, these buckling initiators are specifically tailored and ballasted for controlled buckling, meeting the precise requirements of subsea pipeline specifications. The product is available in various configurations to accommodate different pipe specifications, metocean data, soil conditions, and other project-specific needs.

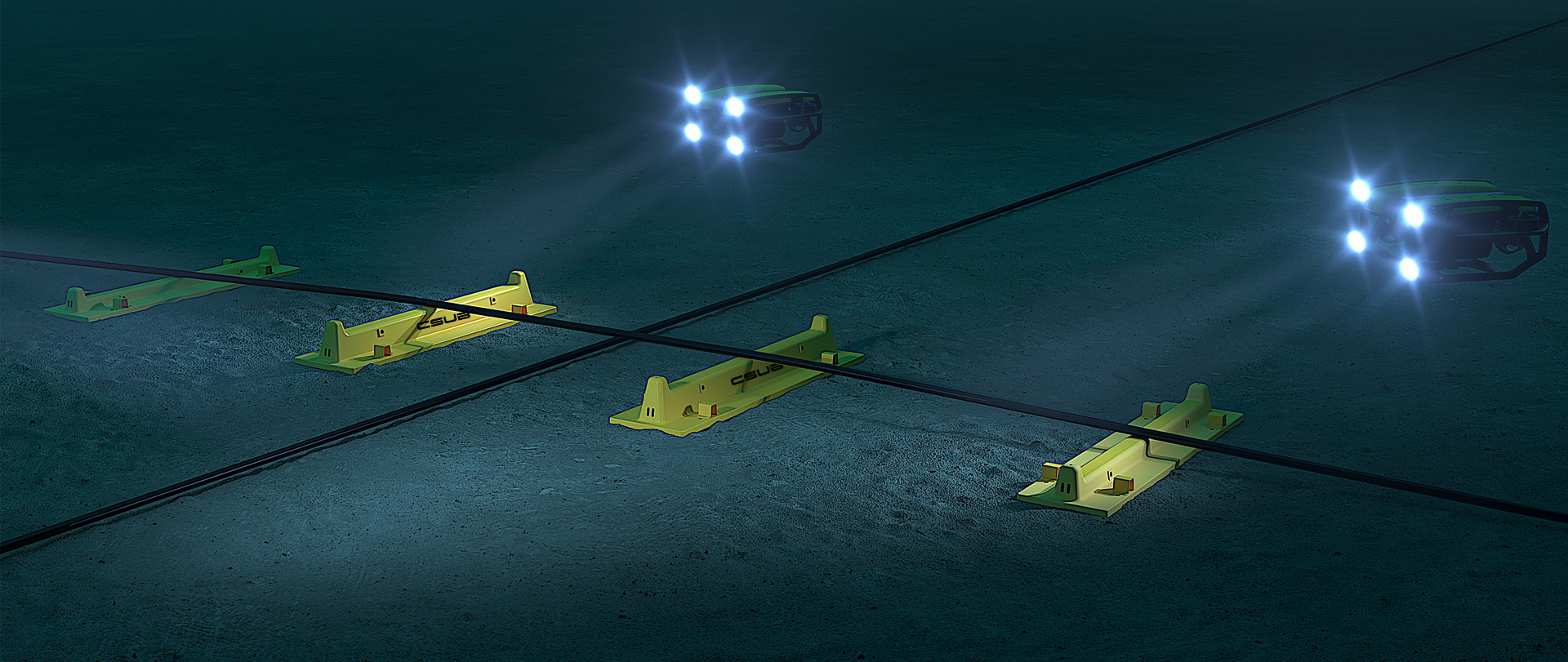

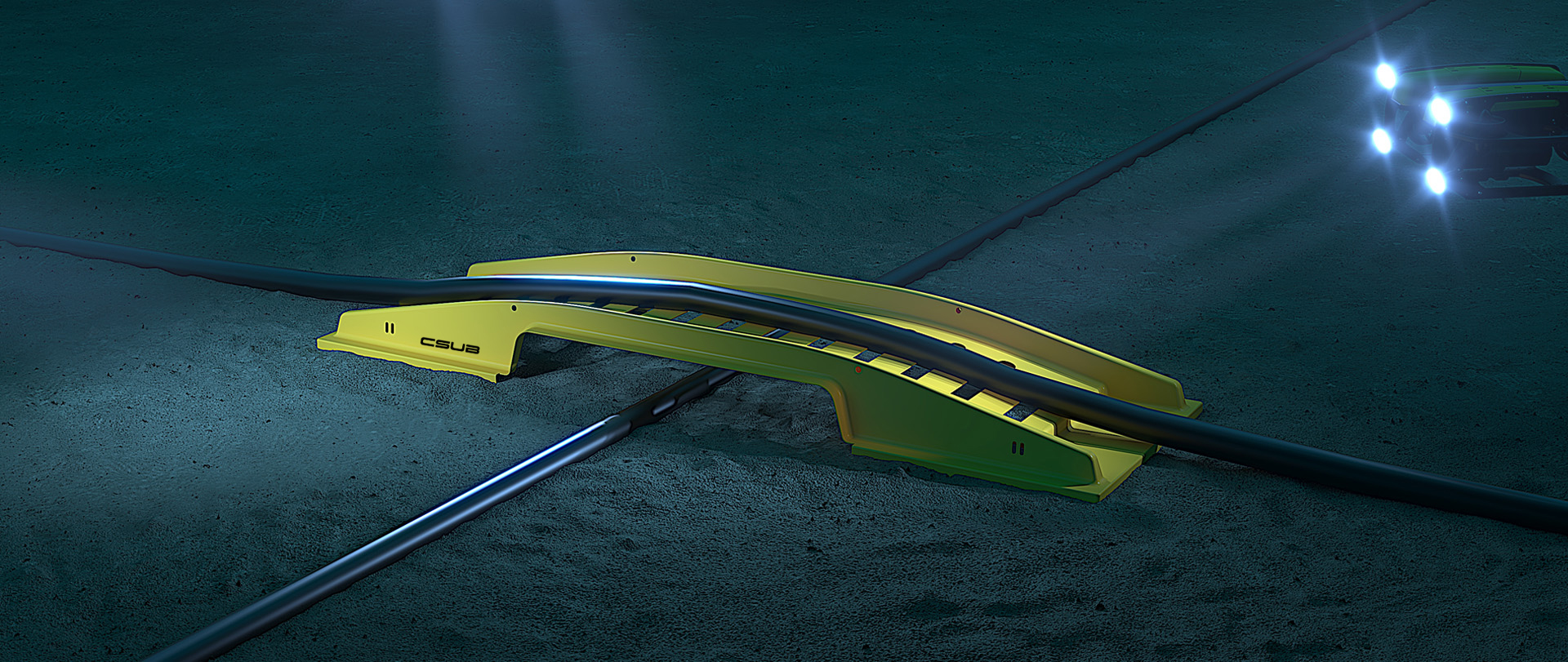

Subsea Crossings and Bridges

CSUB’s crossing structures are engineered to facilitate seamless and safe crossings for subsea pipelines and umbilicals. Designed to ensure minimal environmental impact and straightforward installation, these structures are essential for maintaining the integrity and efficiency of subsea infrastructures.

Pipeline Freespan Correction

CSUB offers specialized support structures designed to stabilize pipelines and spools experiencing challenges with free span control. Our solutions are engineered to be deployed post-installation, providing effective responses to issues such as seabed scouring.

Foundations

CSUB’s GRP Support Structures are engineered to provide support for pipelines, subsea structures, and equipment across challenging marine environments. These structures are pivotal in diverse applications such as buckling mitigation for pipelines and providing firm landing areas for flexible risers.